K2 3.0-3.8T Lithium

OVERVIEW

Lithium Battery

3,000KG – 3,800KG Capacity

Lifts Up To 6,000MM*

Turning Radius 2,400MM

Powerful Performance, High Efficiency

Smart and Safe, Ease in All Aspects

Optimised Ergonomic Design, Better Driving Comfort

K2 Series

It is time to replace your engine-powered trucks. The K2 series forklifts are based on the platform of internal combustion forklifts, but with a battery electric fuel source. This gives the operator the best of both worlds. An electric battery forklift with the functions and usage options of an internal combustion forklift.

Benefits

• The voltage is increased from 80V of traditional lithium battery powered truck to 153.6V. The overall energy efficiency is significantly improved by increasing of the motor power and reducing of the current of motor and controller.

• Permanent magnet synchronous motor for electric vehicle which has lighter mass com pa red with the same energy three- phase a synchronous motor is adopted and the comprehensive efficiency is significantly improved by 20%.

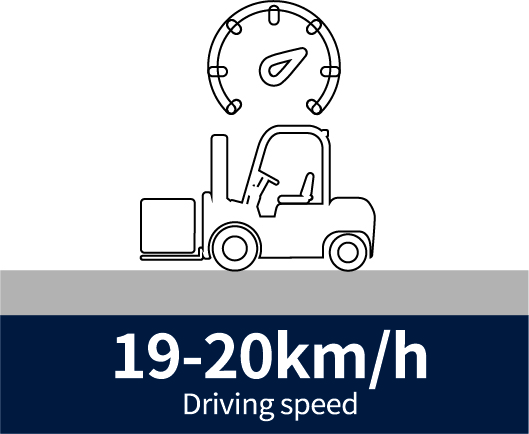

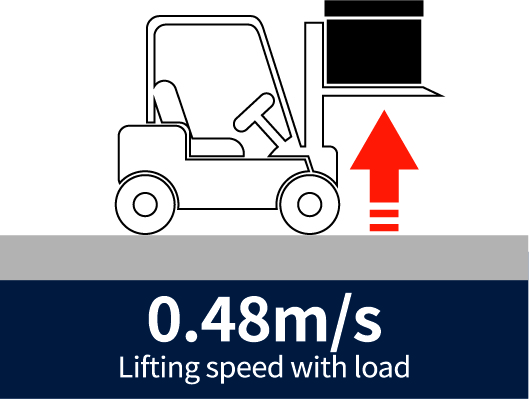

• Superior comprehensive performance and significantly improved operation efficiency, which is superior to fuel truck.

• Integrated fan and water tank makes truck high efficiency and energy saving;

• The electric control of the motor is cooled in real time to minimize the shutdown caused by overheating of controller and motor;

• Hydraulic oil heat dissipation is equipped as standard to ensure the service life of hydraulic components and seals.

• Standard configuration of small diameter steering wheel with handle ball makes steering operation more comfortable;

• The seat is spacious and comfortable and there is more spacious leg space as internal combustion model because of the adoption of the internal combustion truck platform;

• Wide view mast taking from internal combustion models offers wider working field of vision and safer operation;

• USB power setting of instrument panel makes mobile phone charging more convenient;

• MSD maintenance switch realizes power cut off by one key and makes trucksafe and reliable;

• The national standard charging socket makes it more convenient to charge at any time.

• The instrument interface comprehensively displays the basic information such as speed, electric quantity, service time and fault code, which is safe and efficient;

• The instrument is set with option button, and the auxiliary page can display the detailed information such as current, voltage, motor speed and motor electric control temperature Af the same time, the test options such as fan and electronic water pump are set to facilitate after-sales maintenance and inspection.

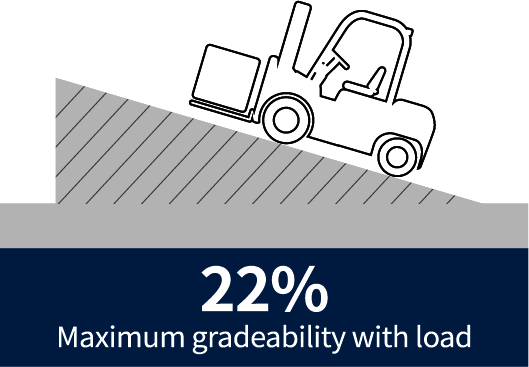

• Integrated casting drive axle and reinforced casting steering axle have been proven by the market and are mature and reliable;

• The mast and truck body of K2 series trucks have stronger bearing capacity, higher stability and safety;

• The test of main parts shall be fully verified to ensure reliability and safety.

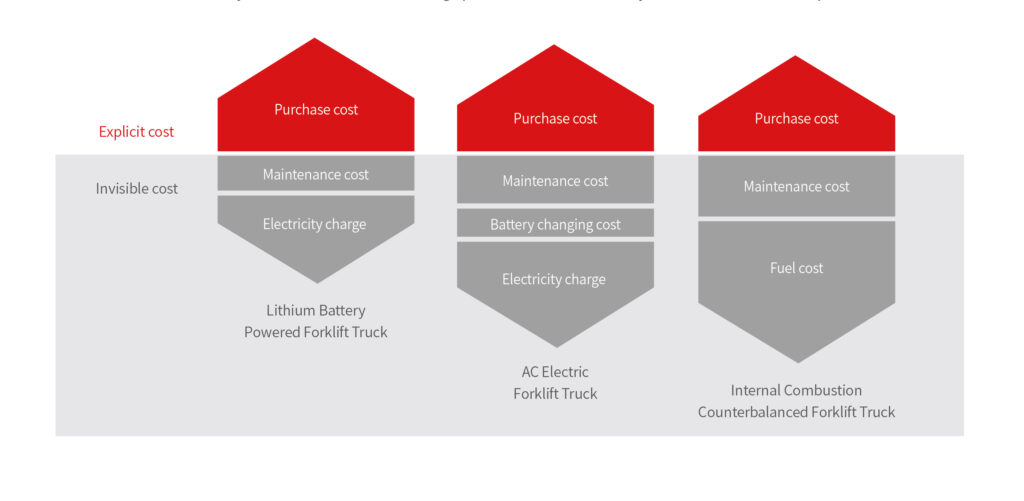

Operating Cost Comparison

Lithium battery forklift vs. Lead-acid battery forklift vs. IC forklift

WoodEvo has opted for Heli Forklifts as their preferred choice due to the remarkable combination of reliability, efficiency, and innovation that these forklifts offer. Heli Forklifts are renowned for their robust design, ensuring durability and longevity in demanding industrial environments, such as those encountered in the wood processing industry. Additionally, the advanced technology integrated into Heli Forklifts enhances operational performance, providing WoodEvo with the precision and productivity needed to streamline their material handling processes. The ergonomic design of Heli Forklifts also promotes operator comfort and safety, contributing to a more efficient and secure working environment. Overall, the decision to choose Heli Forklifts reflects WoodEvo’s commitment to quality, performance, and the seamless integration of cutting-edge equipment into their operations.

Brilliant Logistics International is delighted to utilize Heli Forklifts as a pivotal component of their operations due to the exceptional reliability and efficiency offered by these forklifts. Heli Forklifts have consistently demonstrated a robust performance in material handling, ensuring seamless and timely logistics operations for Brilliant Logistics. The advanced engineering and cutting-edge technology integrated into Heli Forklifts contribute to heightened productivity and precision, aligning perfectly with Brilliant Logistics International’s commitment to delivering top-notch services. The ergonomic design of the forklifts enhances operator comfort and safety, fostering a positive working environment. With Heli Forklifts, Brilliant Logistics International not only ensures the smooth flow of their supply chain but also underscores their dedication to quality and innovation in the logistics industry.

Future Recycling expresses satisfaction with Jialift’s ability to source custom forklift attachment solutions, attributing their happiness to the tailored approach that Jialift employs to elevate their business. Jialift’s commitment to providing specialized forklift attachments aligns seamlessly with Future Recycling’s unique needs in the recycling industry. The versatility and adaptability of these customized solutions have proven instrumental in optimizing material handling processes, enhancing efficiency, and ultimately lifting the overall productivity of Future Recycling. The collaborative effort between Future Recycling and Jialift reflects a strategic partnership that recognizes the importance of innovation and personalized solutions in meeting the specific challenges of the recycling business.

Other Products in this Range