G3 1.5-2T Three Wheel Lithium

OVERVIEW

Lithium Battery

1,500KG – 2,000KG Capacity

Lifts Up To 6,500MM*

Turning Radius 1,545MM – 1,675MM

Powerful Performance, High Efficiency

Smart and Safe, Ease in All Aspects

Optimised Ergonomic Design, Better Driving Comfort

G3 Series

The G3 Series forklifts are the perfect combination of aesthetics and functional design. Boasting a new generation of groundbreaking characteristics to ensure smart, safe, high efficiency, energy saving and environmentally friendly use for every operator. The G3 series is a low maintenance and long life option that is sure to aid any business operation.

Benefits

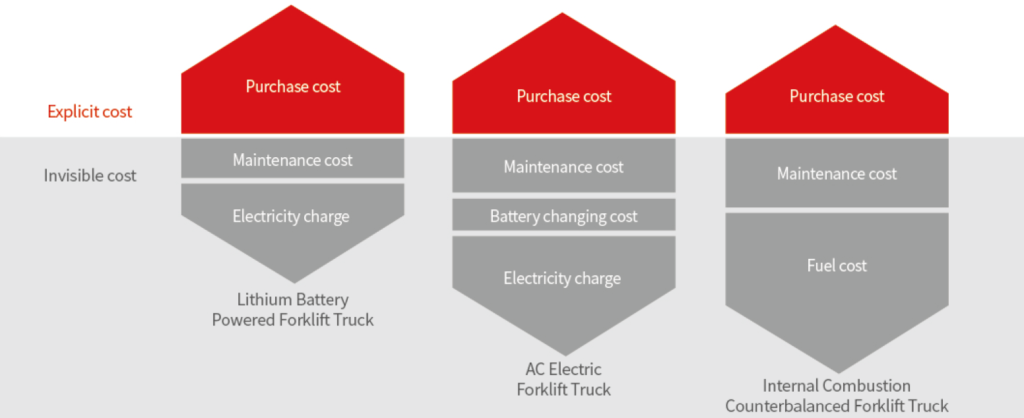

Operating Cost Comparison

Lithium battery forklift vs. Lead-acid battery forklift vs. IC forklift

Other Products in this Range