MIMA Three way

OVERVIEW

Diesel Engine Forklift

1,000KG – 1,600KG Capacity

Lifts Up To 14,200MM*

Turning Radius 1,850MM – 2,235MM

Powerful Performance, High Efficiency

Smart and Safe, Ease in All Aspects

Optimised Ergonomic Design, Better Driving Comfort

MF Series

The MF series is a stand-on type reach truck with a load capacity range of 2-3T. The gantry can be moved forward or retracted as a whole. It also has a small body and turning radius for higher efficiency. This makes the machine perfect for narrow aisles.

MC Series 1.2-1.6T 3-way pallet stacker (Stand-on Driving type)

3-way stacking function: forks can rotate 180° and do left-right side shift without body turning.

The 3-way pallet stacker is the first choice of intensive storage, which is mainly used in logistics, medicine, food and low-temperature cold storage.

● Stacking in ultra-narrow roadways and high shelf design;

● Horizontal handling;

● Load/unload cargos.

VNA Forklift | 3-Way Electric Pallet Stacker

Main Features

1.3-way pallet stacker forks can rotate 180°and do left-right side shift without body turning, with high strength mast design. Min. net channel: 1500mm; Max. lifting height: 9000m. The 3-way pallet stacker can improve space utlization and increase the storage capacity.

2.Advanced Curtis controller and more stable, safer whole-AC system for high efficency, energy conservation and environmental protection.

3.Maintenance-free whole-AC driving system for quick and accurate reaction. Maintenance-free motor, with long service life and low noise and low maintenance cost.

4.Standard electric power steering is safe and reliable, with easy and comfortable operation.

5.Large section mast structure design to ensure the rigidity of mast and improve loading performances, which is very suitable to high shelf storage.

6.Imported hydraulic parts for stable and reliable hydraulic system.

7.Side pull type battery for convenient charging and maintenance.

Advantages

Safe

●Regenerative braking, mechanical disc braking, double braking, safe and reliable three sets of braking system;

●Rotation, side shift interlock function, avoid the wrong operation in the roadway, ensure the safety of the driver operation;

●The lifting system with descending buffer and lifting electronic limit ,which can offer good buffering when goods descended the lowest and rised the highest ,to make sure smooth and safe operation.

●High definition wireless video system ensures driver’s vision during high stacking, improves work efficiency and safe operation.

Easy to operate, flexible and comfortable

●Standard electronic power steering, light operation, smaller turning radius and narrow body width, flexible and convenient operation;

●Forks can be 180 ° rotation and left and right side shift, which is convenient to handle and stack by three-way forks , improve efficiency;

●With body stability system of rear floating bridge design, improve the stability of high position stacking, comfortable and stable of driving.

High automatic

●Optional magnetic guide function cancels the installation and construction of warehouse and shelf bottom guide rail, greatly reduce the cost of warehouse construction and shorten the construction period. With automatic orbit entry function, automatically corrects the driving directions in roadway instead of manual operation of steering wheel, reducing the labor intensity of driver and improving the labor efficiency. The safety protection for derailment and direction deviation ensures safe driving in roadway;

●Optional height pre-selection function, which can set the lifting height in advance, to achieve semi-automatic stacking operation, greatly reduce the labor intensity of drivers, improve labor efficiency;

●Optional all kinds of safety protection functions, such as lifting and walking safety protection of basic position of forks, safety protection of entry and exit roadway, speed limit of high position carrying and so on.

Benefits

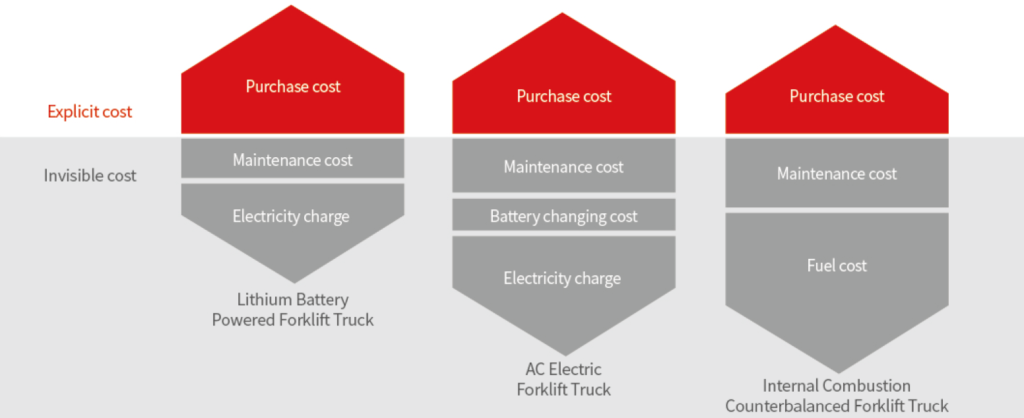

Operating Cost Comparison

Lithium battery forklift vs. Lead-acid battery forklift vs. IC forklift

Other Products in this Range